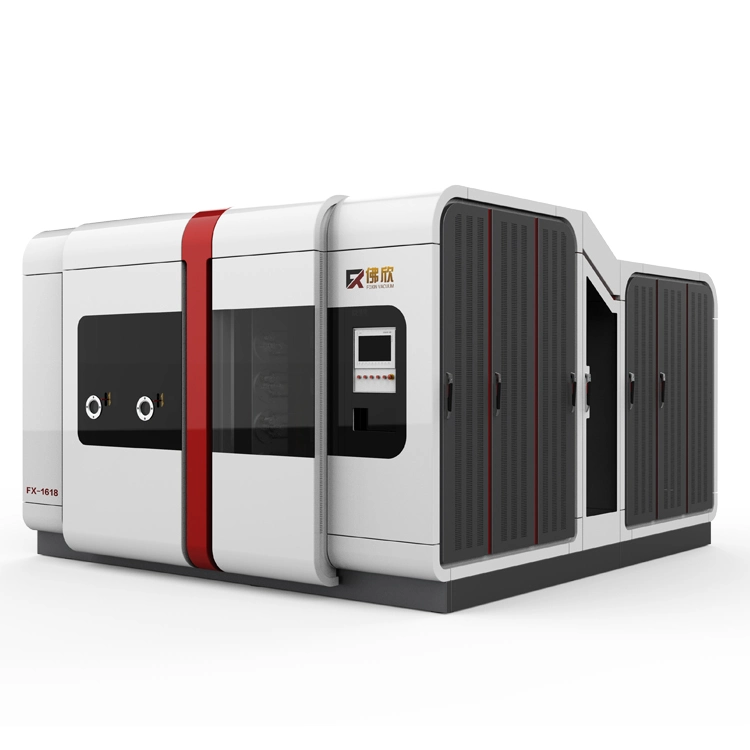

Magnetron Sputter Deposition Machine System

Basic Info

| Model NO. | TG-2040 |

| Condition | New |

| Application | Decorative Coating |

| Install Location | Customer Location |

| Chamber Material | Stainless Steel 304 |

| Control System | Auto &Manual |

| Kinds of Coating | Tin, Ticn |

| Weight | 12 Tons |

| Machine Size | Custom Made |

| Paint Color | Gold, Rose Gold, Blue, Gray, Black |

| Operation | PLC Touch Screen |

| Structure | Vertical or Horizontal |

| Technology | Multi Arc + Sputtering |

| Process | Environmental |

| Working Way | Pumping to Coat |

| Core Selling Point | Long Service Life |

| Transport Package | Wrapping Film |

| Specification | 1600*2000 |

| Trademark | Foxin |

| Origin | China |

| HS Code | 8543300090 |

| Production Capacity | 200 Units/Year |

Product Description

Advantage :High deposition rate ,High ionization rate ,easy operation ,High productivity and Low costApplication :Sanitary Supplies ,Door Lock ,Auto&Motorcycle partsColor: Ti-Gold , Rose Gold ,Black Gold , Coffee , Champagne Gold ,Japanese Gold , Multicolor ,etc.Film Feature :Wear resistance ,Corrosion resistance,High temperature resistance ,Excellent adhesion, Fast colorNote:Specially tailored according to customers' products and process requirements .

We can custom made machine size and configuration according to customer's request

| FOXIN-TG Series Parameters | ||||||

| Model | TG-1010 | TG-1012 | TG-1215 | TG-1620 | TG-1820 | TG-2020 |

| Chamber size(mm) | D1000xH1100 | D1000xH1200 | D1200xH1500 | D1600xH2000 | D1800xH2000 | D2000xH2000 |

| Pumping system | Rough Pump + Roots Pump + Diffusion Pump(Turbo Pump) + Hold Pump | |||||

| Measurement | 1 set pirani, 1 set cold cathode, 1 set diaphragm gauge | |||||

| Arc Source | 6 | 8 | 12 | 18 | 20 | 22 |

| Arc Power Supply | 200A | |||||

| Bias Power Supply | 30KW | 40KW | ||||

| Gas | Ar, N2,C2H2,O2 | |||||

| Cooling | Water cooling circulation, equip with industrial cooling tower or industrial water chiller(refrigerating machine) or cryogenic system.(customers provide) | |||||

| Vacuum Index | Extract time (no load cold state): from atmosphere to 9.9×10-3Pa≤10min | |||||

| Ultimate Vacuum | Superior to 5.0x10-4Pa | |||||

| Pressure Rising Rate | New machine cold state air leaking rate≤0.5Pa/h | |||||

| Running Power(kW) | According to specific configuration | |||||

| Output Frequency | Custom made | |||||

| Occupation Space(m2) | 8 | 10 | 12 | 12 | 12 | 12 |

| Accessory Equipment | Oven, Water Tower, Water Pump, Air Compressor, Jig Rack, Water Tank or Pool | |||||

| Remark | All configuration can be custom made | |||||

Detailed Photos

Our Advantages

Double layer Vacuum ChamberFoxin use double layer of stainless steel 304 to manufacture the vacuum chamber , with advanced welding technology and ensure the air tightness of the chamber . better vacuum pressure protection capability ,higher ultimate vacuum , More durable service life.and built in high power heater and ensure the temperature inside the chamber .Excellent vacuum pumping system

Foxin choose the famous Chinese brand pump for the vacuum pumping system . its Vacuum is fast and steady .to obtain high efficiency coating cycle time , greatly reduces the vibration frequency and energy consumption of the equipment Foxin offer the import brand pump service if the customer required.Foxin's 10th Arc Source and the Parts

Equipped with Foxin's 10th generation high-performance arc power supply and cathode arc source device , it means more uniform coating film , leading reliable performance of continuous coatingFoxin keep the technology R&D , so the technology are progressing . Control System and Famous Electrical Production

Foxin use the international cutting-edge brand s of the electrical production , such as Siemens , Mitsubishi . Especially the PLC .Foxin use the touch screen , easy to control the machine . Automatic system coating system , Foxin will base on the customer's products to set the program . the machine can be finish from pumping to coating automatically.

Company Profile

FAQ

Q1. How about the quality control about your products?

We have the ISO9001 QMS , CE certification.

All machine will past the internal quality test and field testing.

Q2. Does your company provide after-sale service ?

Yes. We have the field engineer to set-up and debug the machine .

After the machine is fully running . we have one year of quality warranty and full-life maintenance service .

Q3. Can you provide technical support about my work-flow?

Yes . The Foxin have more than 20 years of experience in Vacuum coating territory.

We also have an independent R&D department ,which will solve your production issue.

Q4. Do you provide the second-hand machine ?

No. All machine in Foxin are new .

We don't manufacture the second-hand machine .

Q5. Does your company supply accessories for our spare parts after we bought your products ?

Yes . We can supply you all the accessories especially for some consumable material .